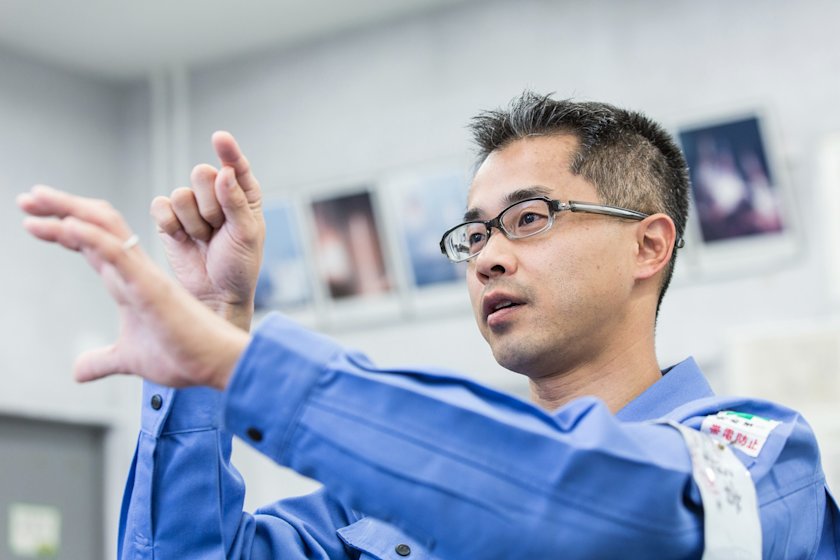

The Tanegashima Space Center has a large Vehicle Assembly Building (VAB), and this facility shoulders great responsibility for Japanese space development with the world’s largest sliding door for rocket launches. Each section of the door is 67.5 meters tall and weighs 400 tons. This gigantic door involves the best technologies of Kawasaki as a multidisciplinary engineering company. The inside story is told by Hideki Mori, an engineer and the section manager.

The Vehicle Assembly Building: Where All Space Rockets Launched from the Tanegashima Space Center Are Assembled

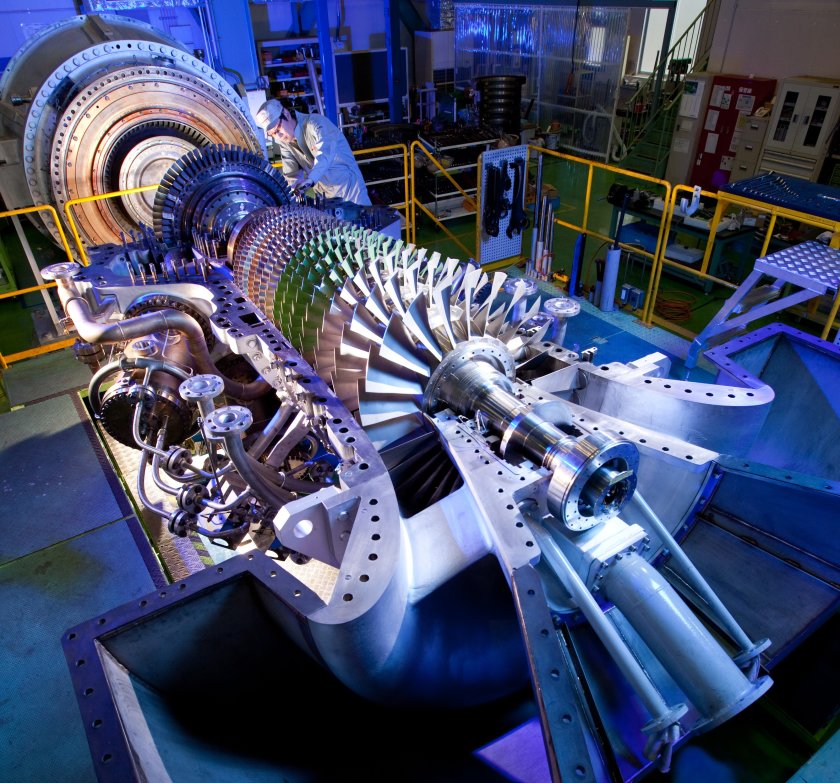

The Vehicle Assembly Building (VAB) is the assembly hangar for large-scale rockets at the Tanegashima Space Center, which is run by the Japan Aerospace Exploration Agency (JAXA). Constructed in 1999 for H-II A rockets, it was modified in 2005 to accommodate H-II B rockets as well. It had been in service for 17 years. Before a launch, the first and second stages of the rocket and the solid rocket boosters are erected and assembled in the VAB. After the mounting of the fairing, which contains the satellite, the assembly is transported to the rocket launch pad. The sliding door of the VAB where the rockets are assembled and readied for launching is one of the highlights of Kawasaki’s technology. As a matter of fact, it is the largest of its kind in the world.

The World’s Largest Sliding Door, According to the Guinness World Record

Each piece of the door is 67.5 meters tall, 27.0 meters wide, 2.5 meters thick, and weighs 400 tons. Driven by hydraulic motors, the door was noted as the world’s largest in the 2005 Guinness World Records. Before the age of H-II A rockets, the VAB had a split gate with suspended (i.e., hanging) doors. When the H-II A rocket came into being, a “sliding-type” construction was adopted, with lateral motion in the manner of Japanese fusuma and shoji sliding doors.

At first glance, this may look like a simple enough design, but the unparalleled size and weight make it a structure which must function properly on the launch date. That is why, even from the initial structural design stage, engineers at Kawasaki were planning and analyzing with all kinds of scenarios in mind.

A Successful 16-year Launch History Based on Kawasaki’s Proven Technology Backed by Analytical Ability

Mori: “The history behind the decision to install a sliding door at the VAB was long and complicated. Actually, three design propositions were brought up: a suspended type, a sliding type, and a swing type. Technically, each of the three propositions would have been possible. However, the VAB was constructed based on the concept of enabling successive launches, requiring room to assemble two space rockets simultaneously. This increased width of the VAB needed to be taken into consideration.

With a suspended-type door, weight would have been a problem. We did consider weight reduction, but that would have meant less structural strength. A swing-type door would have taken care of the weight problem, but with the disadvantage of having a complicated drive unit. Another issue was that both types seemed potentially vulnerable to the typhoons that frequently hit Tanegashima. After thoroughly reviewing all three types, we chose the sliding-type door, which was found to excel in all respects. For its drive unit, we chose a hydraulic system – a strength of Kawasaki – out of concern over potential magnetic-wave damage to sensitive satellite and rocket components, and with a view to explosion-proofing should there be an accident.

All of these considerations resulted in the creation of a sliding door that, over the course of 16 years, has never caused a problem interfering with a launch.”

Raising the Curtain on Japan’s New Space Industry

All of the thirty H-II A rockets and five H-II B rockets assembled at the VAB (as of February 2016), which were designed and built by Kawasaki, have successfully reached to their destinations in space.

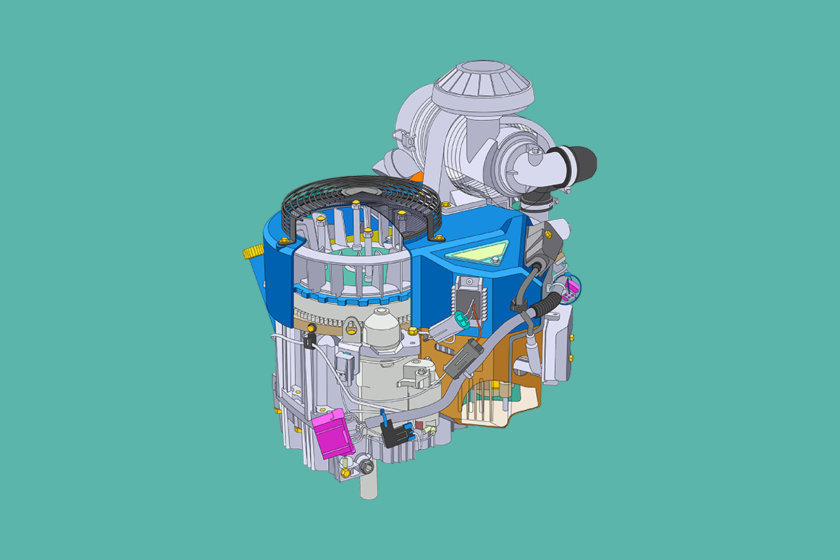

The next stage ahead is the H3, a new flagship launch vehicle, with its first flight scheduled for 2020. Kawasaki is currently planning modifications to the VAB to accommodate these H3 launch vehicles, which will supersede the H-II A and H-II B types. The H3 type, which will take Japan’s space industry into the next era, will be assembled, like the others, in this VAB with the world’s largest sliding door. And when the door opens, the curtain will rise on a new act in the development of Japan’s space industry.

An Affinity for Space Projects and a Sense of Responsibility Are the True Forces Powering Space Rocket Flight

Mori: “What’s motivating us is an affinity for space projects and our sense of responsibility. Naturally, as an engineer I take pride in my involvement in the space industry. Working in this field requires skill, enthusiasm, and resilience, and an array of other capabilities. All of this builds on a sense of attachment to the space industry and my responsibility as an engineer.

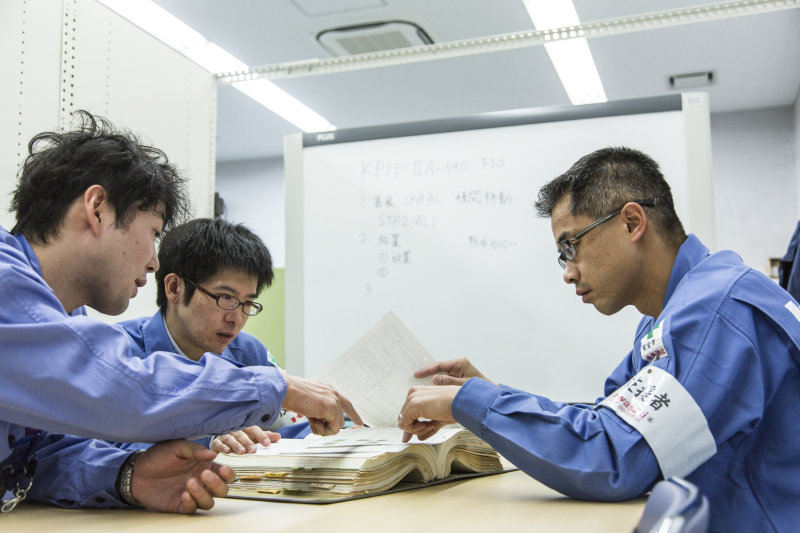

For a rocket launch to be successful, every manufacturer involved needs to execute its particular mission to perfection. Each task needs to be carried out true to standards, within the pre-determined timeframe, with care, and without compromise. In addition, what we need is mutual respect. The Tanegashima Space Center cannot be operated by any single individual. It’s clear to me that, in order to make the Center work, all engineers are supporting each other across company divides. Of course, tempers flare sometimes, but everyone shares in the same ultimate goal, which is getting the rocket successfully off the ground and the satellite on its way. To achieve this goal, we design and operate our individual facilities, and perform maintenance.

We have completed a large number of launches already, but there are more to come. We will keep honing our skills in order to continue planning, operating, and maintaining our facilities, and – in the process – start a new chapter in the space industry.”

Cryogenic Storage System Department

Cryogenic Storage System Engineering Division

Plant & Infrastructure Company

Kawasaki Heavy Industries, Ltd.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment