From LNG Carriers to Liquefied Hydrogen Carriers

Kawasaki has developed many innovative technologies that have become industry standards for LNG carriers. Today, those technologies underpin the world’s energy transportation.

Japan pioneered the use of LNG as an alternative energy source that produces less CO2 emissions when burned than oil and coal. The decision to chart this new path was made out of a need to combat pollution. As a result, LNG started to be produced in larger amounts, prompting a need to reduce costs and develop related technologies, and it went on to become a major global energy source.

However, transporting liquefied natural gas, cooled to -163°C, presented a huge technical challenge. Kawasaki introduced the Moss-type tank technology developed by Moss Rosenberg Verft A.S. of Norway to overcome this challenge, and built Asia’s first LNG carrier Golar Spirit in 1981. Kawasaki subsequently went on to become a global leader in LNG carriers, especially in the field of Moss-type spherical tanks. As of December 2014, Kawasaki had built 29 Moss-type LNG carriers, ranging in tank capacity from 19,400m3 to 177,000m3.

Numerous technological innovations were introduced along the way, including the Kawasaki Panel System, a thermal insulation system that is now an industry standard. Energy Horizon, completed in 2011, featured cargo tanks boasting the world’s largest capacity, while ensuring that the hull size remained compatible with the world’s major LNG terminal ports.

First Model Golar Spirit

First LNG carrier developed in Asia. Featured five Moss-type independent spherical tanks made of aluminum, boasting a total capacity of 129,000m3. Served as a model for the large LNG carriers built thereafter.

Energy Horizon

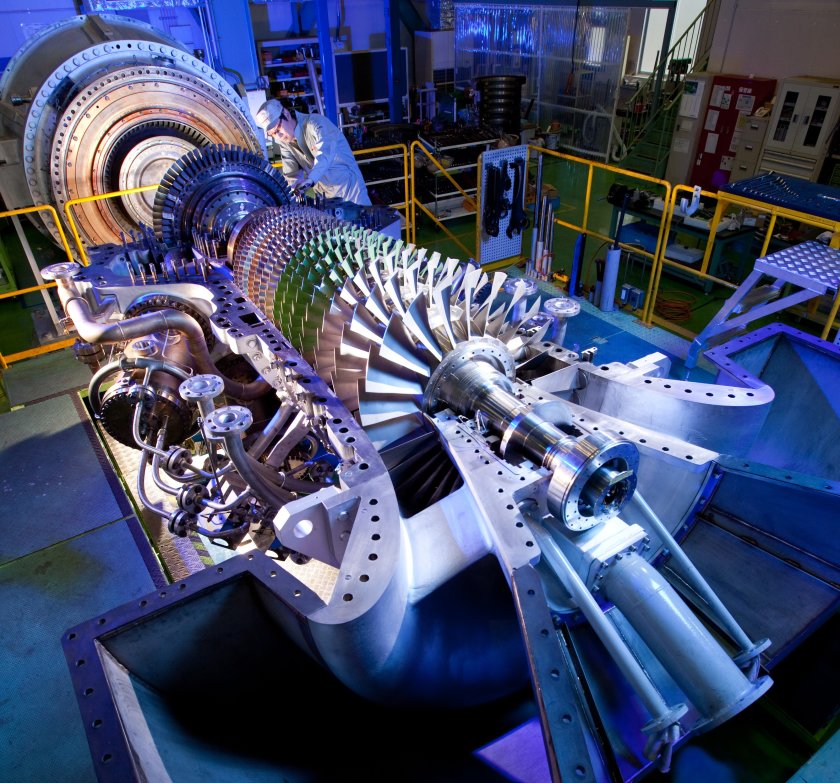

A highly efficient and versatile carrier with a world-leading tank capacity of 177,000m3, and a hull size compatible with the world’s major LNG terminal ports. Adopted the Kawasaki Advanced Reheat Turbine Plant, the world’s first reheat cycle plant to power an LNG carrier. The steam used to drive the high pressure turbine is returned to the boiler to be reheated, then sent on to the intermediate pressure turbine. The system reduced fuel consumption by about 15% compared to previous plants.

Liquefied hydrogen transportation Pioneering test vessel

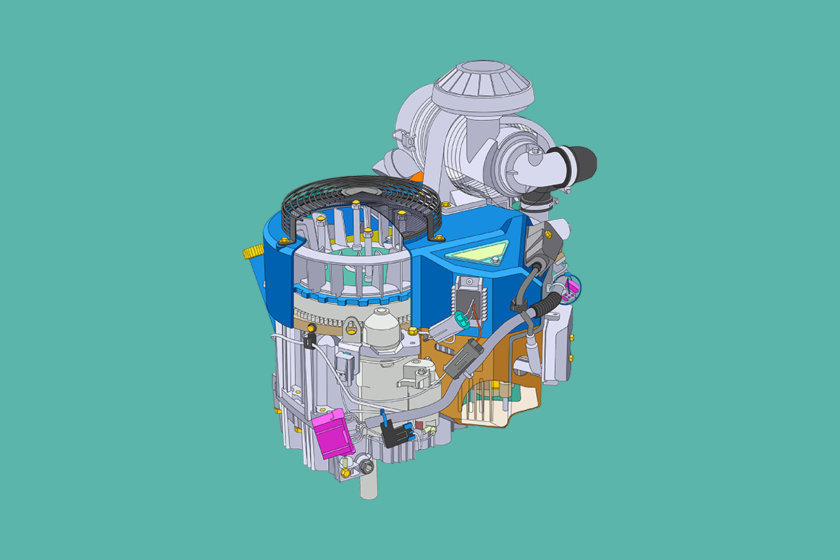

Kawasaki is currently developing a pioneering test vessel for the marine transportation of liquefied hydrogen. The vessel will have a cargo capacity of 2,500m3, equivalent to that of coastal trading LNG vessels. Kawasaki obtained approval in principle from Nippon Kaiji Kyokai (ClassNK) for the cargo containment system in 2013. Kawasaki aims to complete development design in 2016, then subsequently move forward with commercialization.

Liquefied hydrogen evaporates at a rate 10 times greater than LNG. To accommodate this, the pioneering test vessel will employ a cargo containment system of a double shell structure for vacuum insulation, offering support that demonstrates excellent insulation performance and safety.

FUTURE -Liquefied hydrogen carrier

A liquefied hydrogen carrier that heralds the dawn of a new era of hydrogen energy. In the near future, when hydrogen comes into wide use in society, hydrogen produced overseas at a low cost will need to be transported in large amounts. To help support this global distribution of hydrogen, Kawasaki is aiming to develop a large liquefied hydrogen carrier with a capacity of around 160,000m3.

Now the technologies used in LNG carriers are being carried over to liquefied hydrogen carriers. With a specific gravity only one-sixth that of LNG, liquefied hydrogen must be transported at a temperature of -253°C, close to absolute zero.

Kawasaki has already obtained approval in principle from Nippon Kaiji Kyokai (ClassNK) for its cargo containment system to be installed on liquefied hydrogen carriers. Kawasaki will continue to move steadily forward as a pioneer in the marine transportation of liquefied gas.

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment