All employees, from the Accounting Department to the Quality Department, from cafeteria staff to cleaning staff, share information. We have to have the mindset that good and bad news (production defects, financial issues, etc.) should be shared in order to make good decisions regarding the manufacture of our products. Employees who want to improve, seek to broaden their perspective and knowledge of the overall business situation.

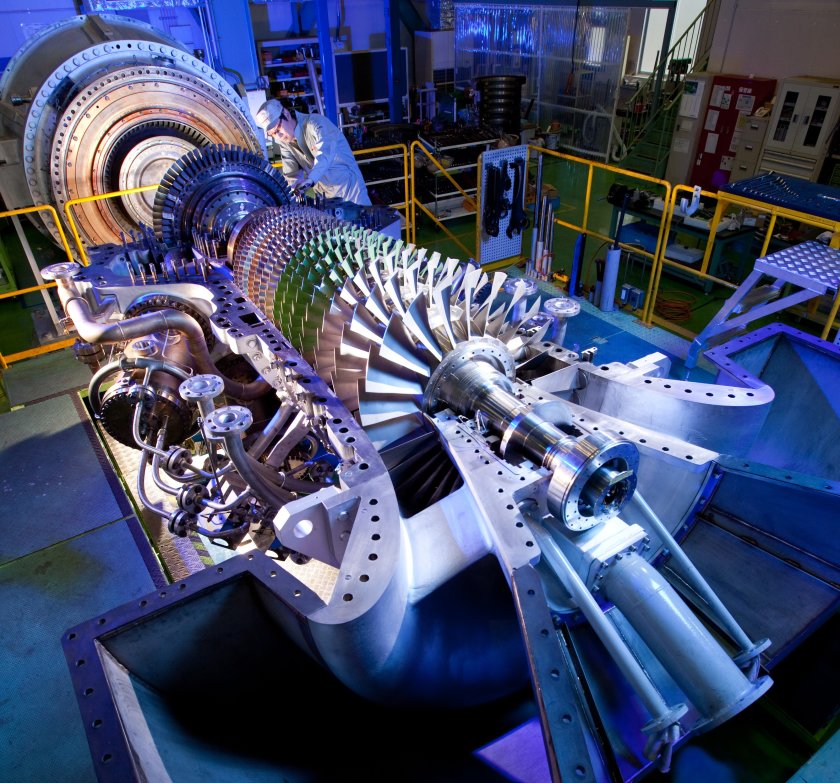

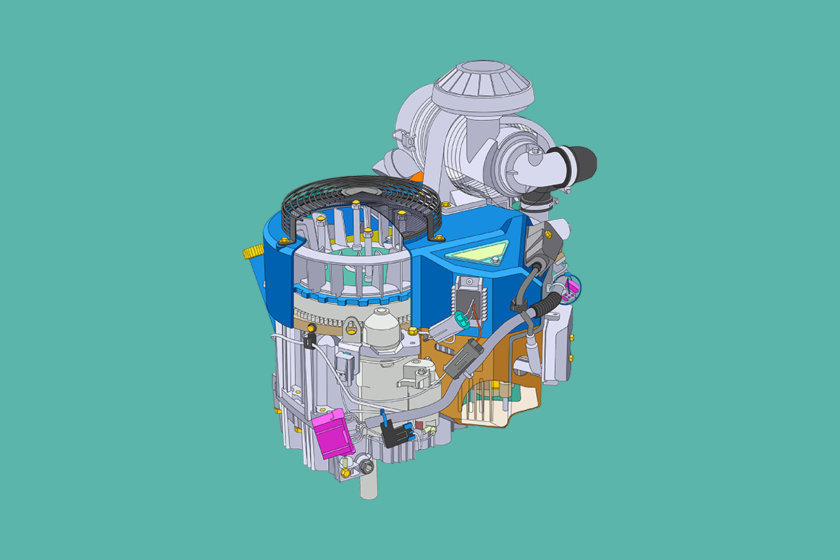

General-purpose engines for professional lawnmowers, powerful enough to keep running at full throttle

I entered KMM as the Human Resources Administrator for the Maryville Plant in 1989. The Maryville Plant manufactures “general-purpose engines” for the lawn and garden industry. Our general-purpose engines have received overwhelming support from major manufacturers of lawnmowers due to their powerful performance.

In the U.S., our business is reflective of housing development and weather conditions. This continues to drive demand and is keeping the Maryville Plant at full production. However, the population of Maryville is only around 12,000; 1,100 of whom are working at our company. We continue to try to add employees to fill open positions. However, the good economic con-ditions provide many jobs and many employers are experiencing the lack of employees.

The Lincoln Plant has supported the Maryville Plant by establishing an assembly line for Long-Block engines to feed into our finished engine assembly process in Maryville.

We are making strong efforts for improvements to enable streamlined production which requires less manpower. Every year, we receive fantastic ideas from our workforce on improvements to efficiencies, processes, safety items, etc… These ideas are presented by the employee(s) to top management personnel every six months. These improvement ideas continually raise the level of KPS throughout the plant.

Through Kawasaki Production System (KPS), we strive to standardize the work by eliminating waste of any kind. For the operation of Maryville Plant, I think that “standardization” is an important keyword.

It’s vital that employees in all departments communicate and share information – good or bad. We have to have the mindset that good and bad news (production defects, financial issues, etc.) needs to be shared in order to make good decisions regarding the manufacturing of our products and running our business effectively and efficiently. Employees who want to improve, seek to broaden their perspective and knowledge of the overall business situation.

So it is my job to ensure good communication occurs and we, as a team, make the best decisions for our future.

The best engines

The general-purpose engines produced at Maryville are supplied to manufacturers of lawn and garden products. These engines are not only distributed in the USA but also supplied as OEM products to many overseas manufacturers. Kawasaki engines are known for their quality and durability. Currently, in order to respond to increasing demand, the plant continues to operate in full-production mode. New assembly lines have been added as well as new back shop operations being installed in 2018 including a new crankcase line, flywheel line, cylinder head line and a new Die Casting machine.

Kawasaki Motors Manufacturing Corp., U.S.A. (KMM)

![]() Energy and Environment

Energy and Environment![]() Energy and Environment

Energy and Environment